When purchasing the stainless steel cutlery set, buyers often find that two items look similar, but the price differs. Why do similar stainless steel flatware prices vary so much? It confuses many overseas purchasers, catering wholesalers, and hotel supply chain managers. Behind these price differences often lie multiple factors, including materials, craftsmanship, manufacturing capabilities, logistics, and certifications. Without understanding these key factors, it’s easy to encounter quality risks, delivery delays, or hidden cost increases during procurement. Mcallen will analyze market price differences from a professional manufacturer’s perspective and provide procurement decision advice to help you make more rational wholesale choices.

Factor 1: Material Differences Lead to Different Stainless Steel Flatware Prices

The material of stainless steel flatware directly determines its price and lifespan. Common materials on the market include 18/10, 18/8, 18/0, and some special steels.

- 18/10 and 18/8: High nickel content, good corrosion resistance, elegant feel and luster, suitable for high-end catering and hotel projects.

- 18/0: Low nickel content, weaker corrosion resistance, suitable for budget-conscious or low-frequency use scenarios.

Ordinary stainless steel tableware can be found on the market at low prices, but it is not very durable and the user experience is limited. On the other hand, premium quality flatware, though slightly costlier per piece, is superior in terms of corrosion resistance, feel, and overall cost of ownership, particularly for commercial caterers in high-intensity usage.

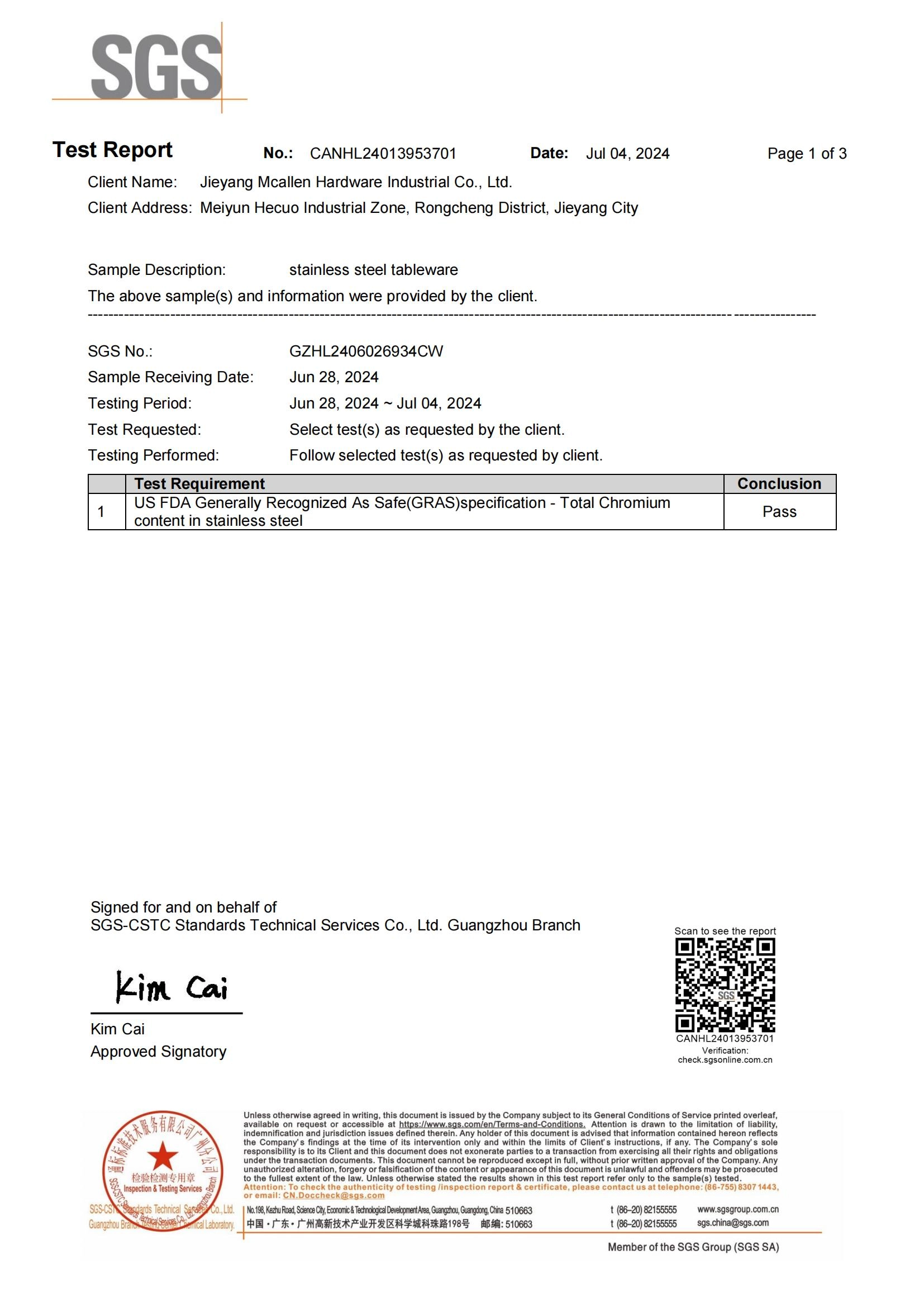

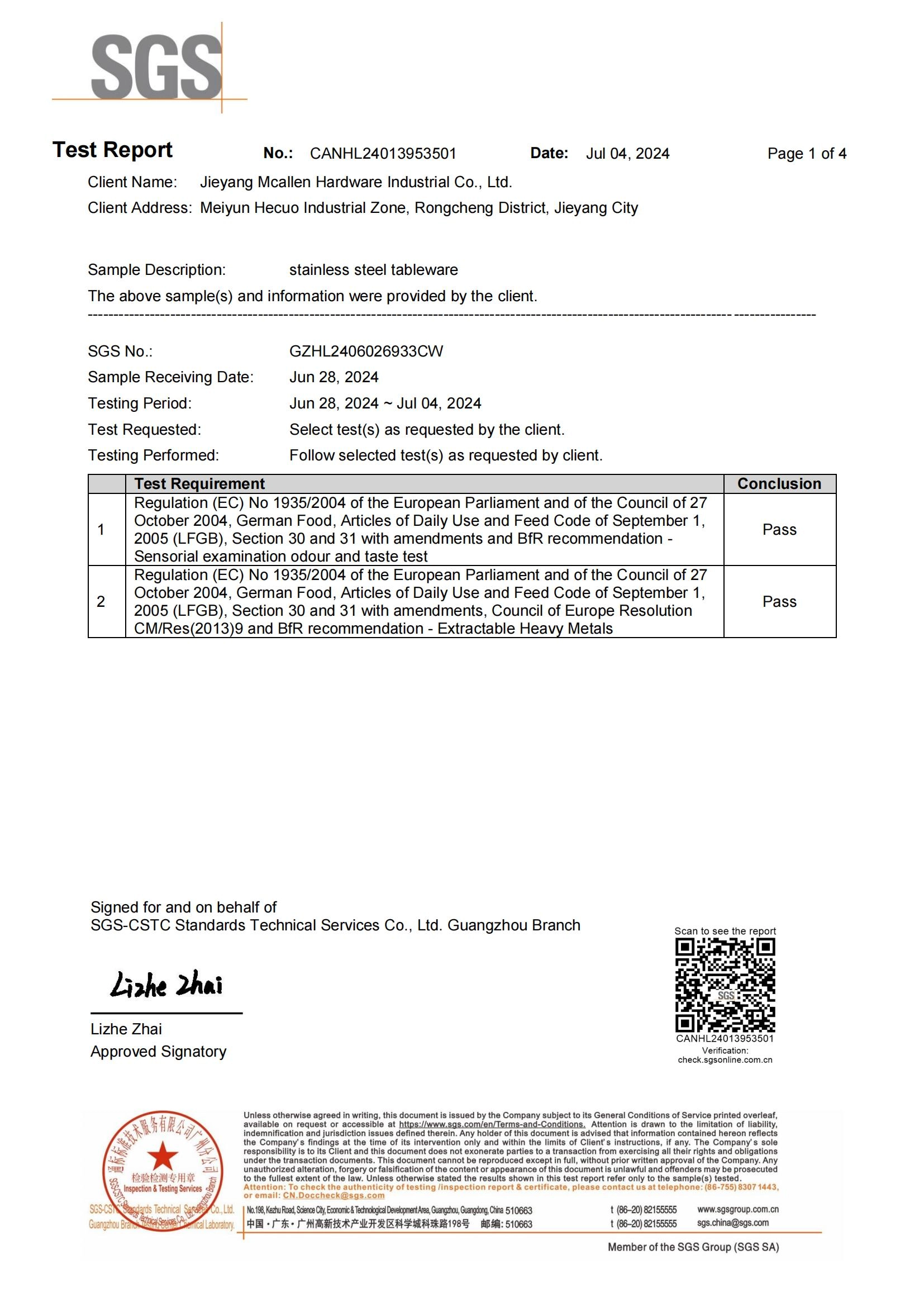

Purchasing Recommendations:

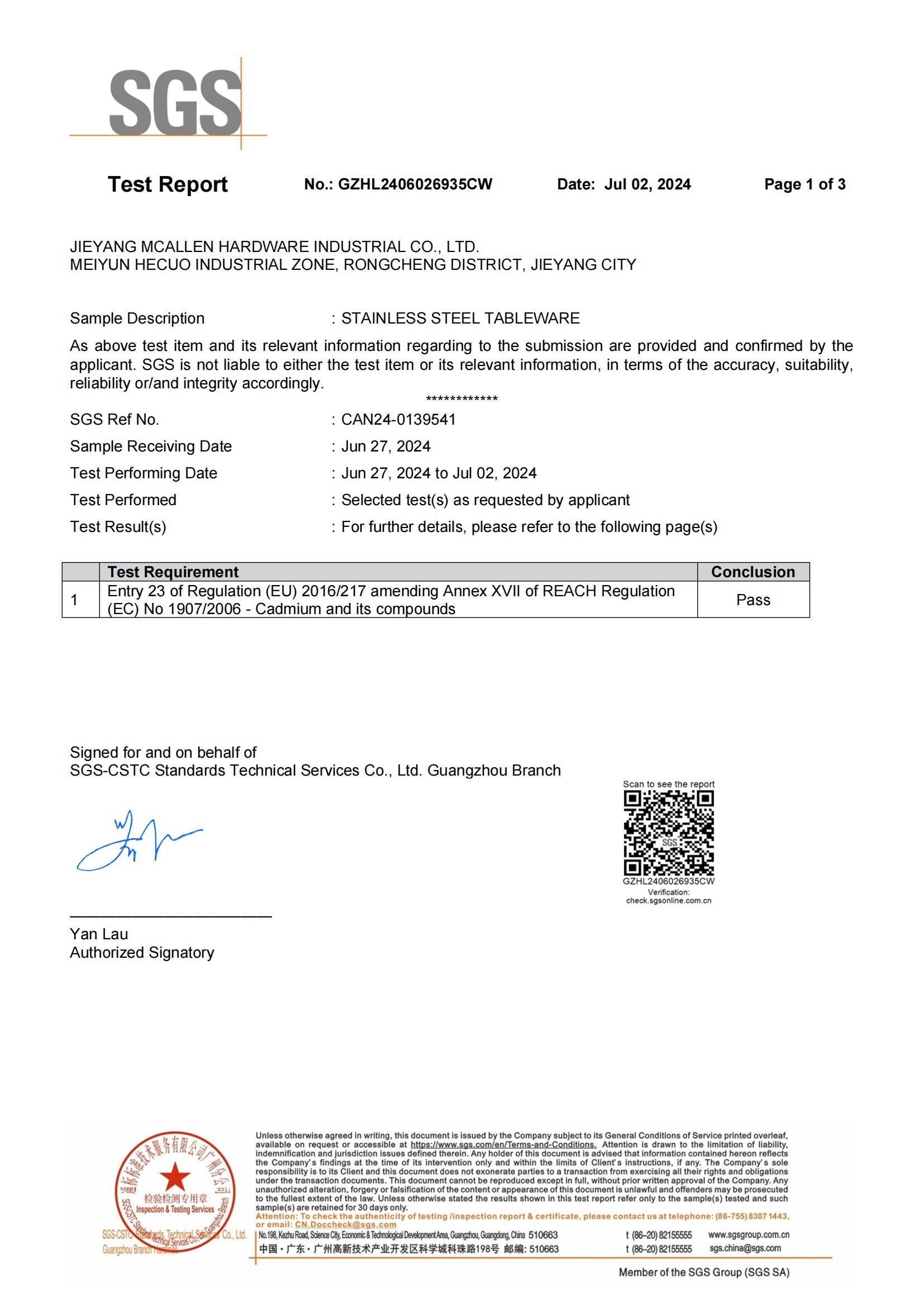

- Request material certificates such as SGS, MSDS, and LFGB to verify the steel grade’s authenticity and reliability.

- Conduct magnetic testing or sample comparison on key components to confirm material consistency.

- Prioritize long-term, stable suppliers to ensure batch consistency.

Mcallen provides quality material tracking and batch consistency, reducing procurement investment risks in the catering industry.

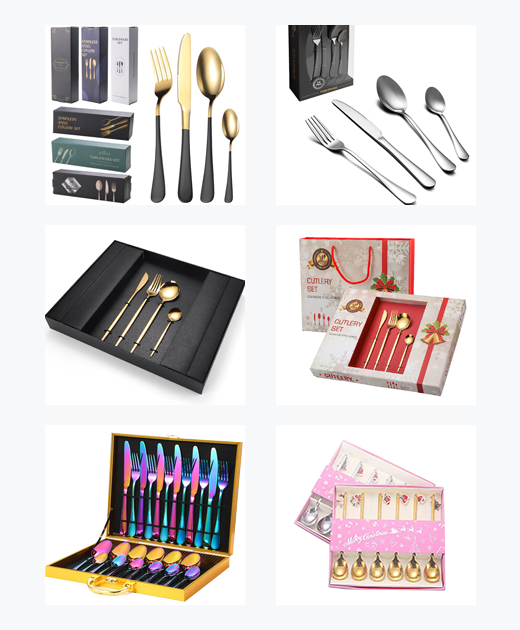

Factor 2: Stainless Steel Flatware Manufacturing Process

Different surface treatments directly affect the cost and selling price of tableware. Common treatments include mirror finish, brushed finish, matte finish, sandblasting, PVD plating, and gold plating.

High-end processes such as PVD or hand polishing require more equipment or labor, resulting in higher costs. Low-priced products may have issues such as large color differences, easy wear, and uneven polishing.

Purchasing Recommendations:

- Request process samples to test color difference, abrasion resistance, and washability.

- Ensure the supplier’s mass production capabilities to maintain sample consistency in bulk orders.

As a reference example, factories with automated polishing and PVD coating production lines can guarantee consistent color and durability across large batches, which helps buyers evaluate supplier reliability.

Factor 3: Factory Production Scale and Quality Control

Factory size and quality control systems significantly impact pricing.

- Small workshops: Limited capacity, high scrap rate, unstable delivery; unit prices may be lower but risks are high.

- Professional factories: Stable production capacity and comprehensive QC system (IQC, IPQC, FQC, OQC), ensuring batch consistency.

Purchasing Recommendations:

- Choose factories with complete QC processes to reduce quality risks.

- Verify factory monthly production and delivery records to ensure supply chain stability.

The long-term reliable factories with strict QC processes and stable production capacity provide a strong reference for B2B buyers.

Factor 4: Packaging, Logistics, and Compliance Cost Differences

Packaging, shipping, and market compliance all affect cost. High-end packaging such as gift boxes and shock-absorbing materials, increases costs but reduces transport damage. Compliance regulations include FDA (USA), LFGB (EU),and UKCA (UK). Low-priced products may omit certifications or use simplified packaging, increasing transport risk.

Procurement Recommendations:

- Define packaging specifications and shipping methods to avoid logistics losses.

- Verify export compliance documents for smooth customs clearance.

Suppliers offering complete export packaging and certification documents are usually more reliable and can be used as a reference standard for procurement.

Factor 5: Flatware Customization and Branding Services

Stainless steel flatware OEM/ODM customization is common in B2B procurement but affects pricing.

- Customization elements: Logo engraving, handle design, gift box packaging

- Small-batch customization costs more than large-batch standard products.

- Market risk: Some suppliers do not support small-batch customization or offer low-quality results.

Procurement Recommendations:

- Establish clear specifications and sample verification processes for customization projects.

- Compare supplier customization capabilities and delivery times to ensure feasibility.

By reviewing sample production, process details, and batch consistency, b2b buyers can evaluate supplier customization capabilities.

Procurement Strategy and Price Evaluation Tip for Purchaser

When evaluating prices, consider more than the unit price:

- Material and process quality

- Factory capacity and quality control

- Packaging, logistics, and certification costs

- Customization service capabilities

Procurement Recommendations:

- Verify samples, compare quotes from multiple suppliers, and review qualifications.

- High cost-effectiveness comes from a comprehensive evaluation of quality, delivery time, and long-term cooperation stability, not just a low price.

Conclusion

The price differences in the stainless steel flatware market are mainly caused by material, process, production capacity, logistics and certification, and customization services.

Procurement Tips Summary:

- Clearly define your procurement needs, prioritizing quality and long-term supply stability.

- Sample verification and qualification review are essential.

- Establishing a reliable, long-term supplier partnership significantly reduces procurement risks.

Mcallen, a leading stainless steel flatware manufacturer, offers stable batch production, strict quality control, and flexible customization services. Contact us for quality stainless steel cutlery set samples, quotations, and OEM/ODM services.