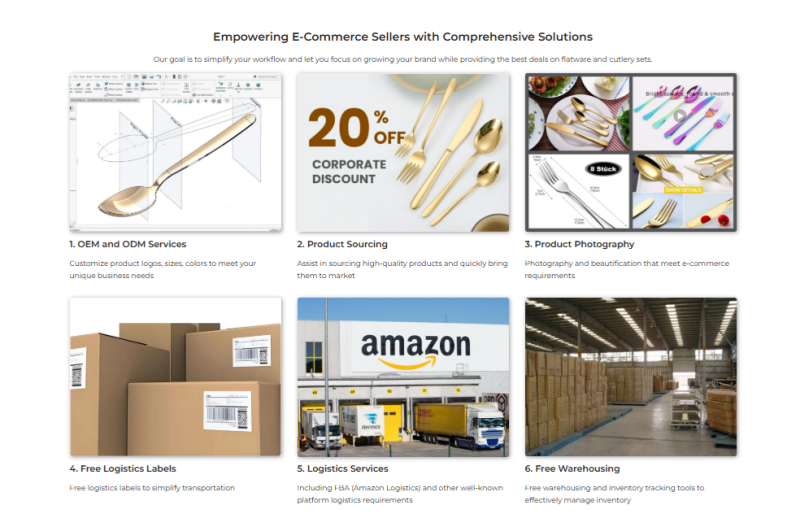

Custom flatware has become an essential tool for the foodservice, hotel, and retail industries to enhance brand image and elevate customer experience. As a professional flatware manufacturer, Mcallen has over 17 years of production experience, providing flatware OEM/ODM services for numerous international brands, restaurant chains, hotel groups, and gift clients. This article will cover all key aspects of custom flatware, including materials, craftsmanship, production capacity, packaging, logistics, and customization services, along with actionable procurement advice to help you make informed decisions.

What is Custom Flatware? Definition and Components

Custom flatware is more than just a logo-engraved knife, fork, and spoon set—it is a tailored solution designed around your brand needs, dining environment, and customer experience.

A typical custom flatware set may include knives, forks, spoons, serving spoons, and sometimes additional tableware accessories. Customization generally falls into three levels:

- Light customization: Logo engraving or simple inscriptions.

- Moderate customization: Handle patterns, surface finishes, and other design enhancements.

- Deep customization: From mold development and handle design to integrated packaging solutions.

Procurement advice: Start with light customization to test market response, and expand customization gradually. Make sure to clearly define the intended usage scenario, fine dining, hotel, or retail, as it affects material and craftsmanship requirements.

Key Design Dimensions for Custom Flatware

Material Selection: Key Factors Affecting Performance and Price

The stainless steel material directly affects the durability, corrosion resistance, and feel of flatware. Commonly available on the market are 18/10 and 18/8 stainless steel, which have high nickel content and an elegant feel, suitable for high-end restaurants and hotels. 18/0 stainless steel is cheaper but less corrosion-resistant, making it more suitable for budget-conscious or low-frequency use scenarios. While a high-quality stainless steel cutlery set may be slightly more expensive per unit, its superior durability and user experience make it more cost-effective overall.

Procurement advice:

- Request material certificates such as SGS, MSDS, and LFGB to verify steel authenticity.

- Perform magnetic testing or sample comparison to ensure material consistency.

- Prioritize long-term, reliable suppliers to guarantee batch consistency.

Surface Finishing and Visual Appeal

Surface treatment not only affects appearance but also the cost of flatware. Common finishes include mirror polish, brushed, matte, sandblasted, PVD coating, and gold plating.

Advanced processes such as PVD or hand polishing require more labor and equipment, increasing costs. Low-priced products may suffer from color inconsistency, poor wear resistance, and uneven polishing.

Procurement advice:

- Select finishes according to usage scenario; high-frequency environments like hotels require durable finishes.

- Request process samples to test color consistency, wear resistance, and dishwasher safety.

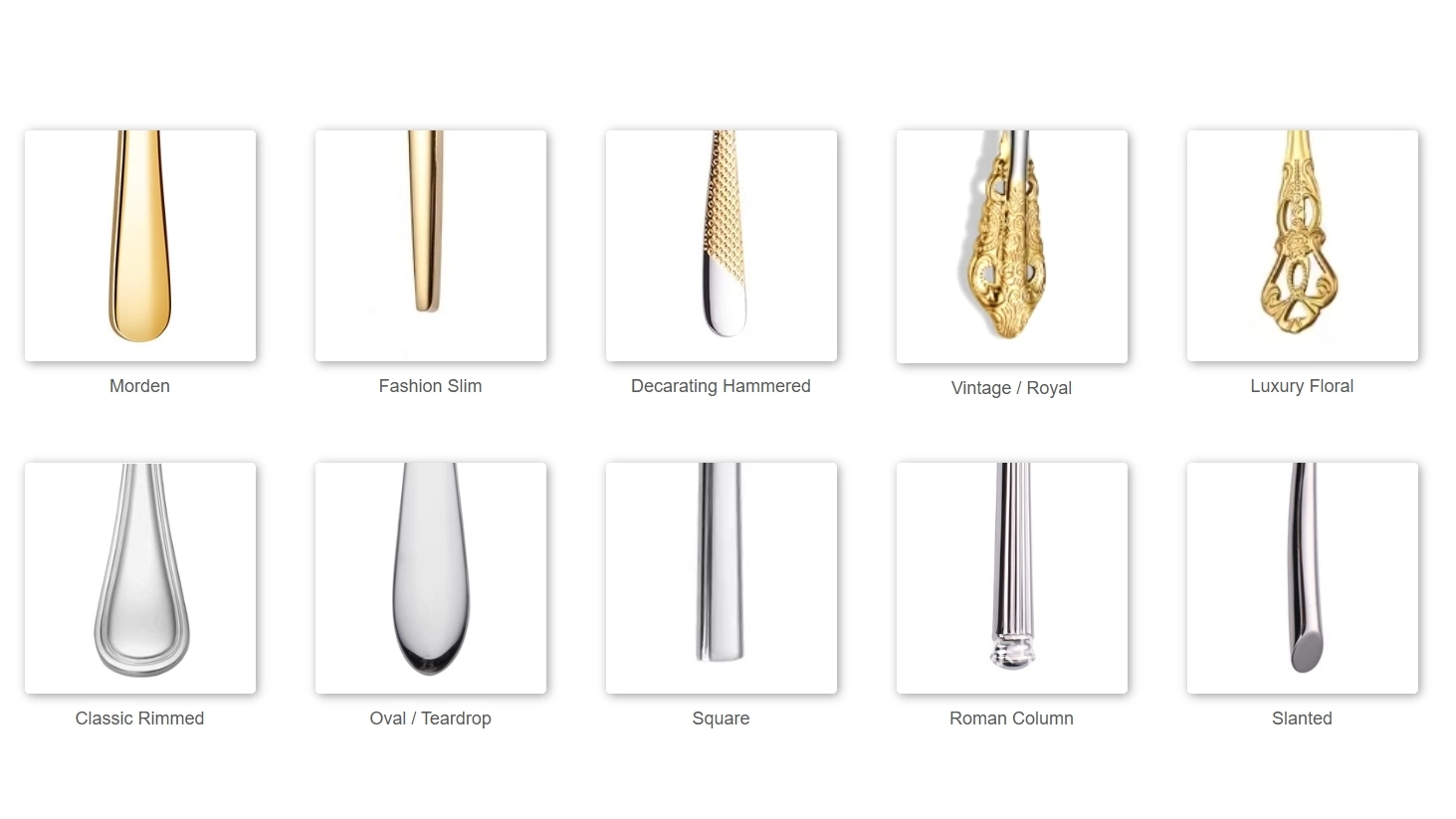

Handle and Shape Design

Handle shape, curvature, and thickness distribution impact user comfort. Popular design styles include minimalist, classic, American, and European.

Procurement advice:

- Match handle design to the intended customer scenario, e.g., fine dining vs casual dining.

- Use samples to verify comfort and ensure mass production matches design standards.

Logo Customization and Brand Identity

Logos are crucial for brand recognition. They can be applied via laser engraving, laser etching, colored inlay, or PVD marking. Logo placement can be on the handle end, side, or packaging.

Procurement advice: Choose logo style and placement according to brand positioning to ensure visibility and aesthetics.

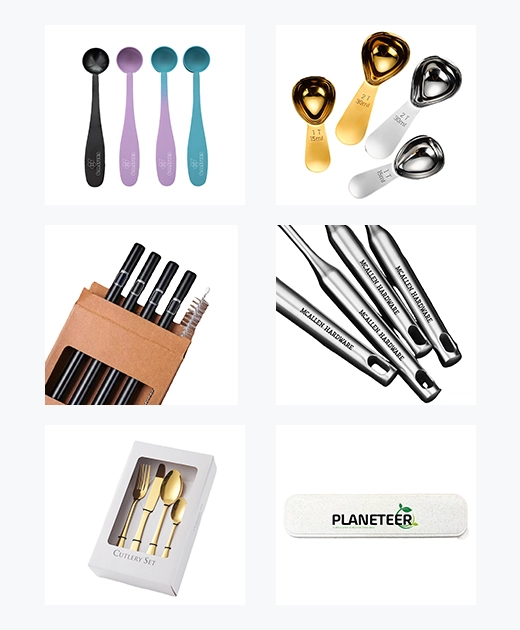

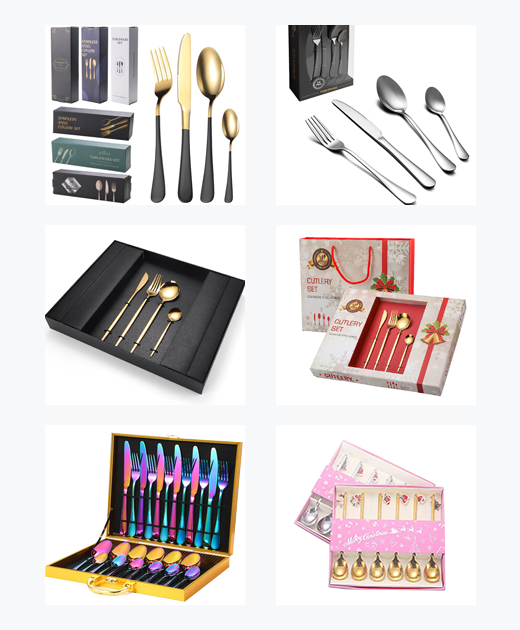

Packaging Customization

Packaging serves both presentation and transport protection purposes. Common packaging options include OPP bags, gift boxes, EVA inserts, luxury wooden boxes, and leather boxes.

Procurement advice:

- Clarify the difference between display packaging and transport packaging.

- Confirm protection standards to minimize shipping damage.

Supplier Evaluation Criteria

Selecting a supplier involves more than price—it requires assessing production capability and quality control:

- Production capability and process transparency: Do they own mold development, stamping, polishing, surface finishing, and logo engraving capabilities?

- Quality management system: Do they have a complete QC process (IQC, IPQC, FQC, OQC) and support third-party inspections?

- Client references and long-term supply ability: Do they have experience with hotels, restaurants, or major distributors, and can they provide a stable batch supply?

Procurement advice:

- Look beyond price and focus on process transparency and long-term collaboration potential.

- Suppliers with automated production lines and strict QC can reduce procurement risks.

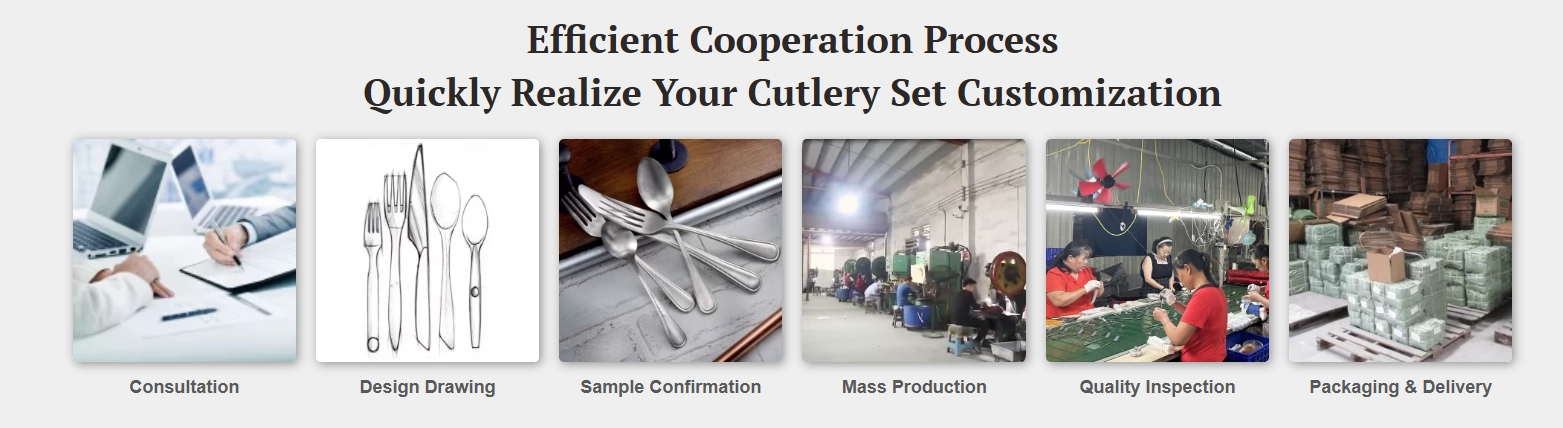

Order Process, Pricing, and Production Planning

- Sample stage: Verify material, feel, craftsmanship, logo, and packaging to ensure samples represent mass production quality.

- Design confirmation: Approve drawings, handle patterns, colors, and logo placement.

- MOQ (Minimum Order Quantity): Different processes and customization levels affect MOQ. Small-batch customization is costlier, suitable for market testing, while large-batch orders reduce mold and process costs.

- Mold development and mass production: New mold development takes 2–6 weeks. Ensure batch consistency during production. Prioritize suppliers with in-house molds and automated lines.

- Lead time: Standard lead times may extend during peak seasons or complex processes. Plan orders in advance to secure supply.

- Quotation components: Material cost, process cost, customization fee (logo, handle pattern, packaging), packaging and shipping, duties and compliance fees.

Procurement advice:

- Create a detailed specification document and confirm samples before placing bulk orders.

- Evaluate overall capabilities through transparent quotations rather than focusing solely on unit price.

- Mcallen’s automated production and structured QC ensure batch consistency and controlled lead times.

Strategies to Maximize Procurement Value

- Start with small-batch production to verify quality and customer feedback.

- Establish long-term agreements and priority scheduling to reduce supply risk.

- Leverage bulk orders to optimize costs while maintaining consistent quality.

Conclusion

The value of wholesale and custom flatware lies not only in appearance but also in the combination of supply chain reliability, design, quality, and service. High-quality customization will greatly improve customer experience and brand image. True customization value comes from long-term consistency and brand experience, not just unit price. Mcallen provides stable batch production, strict quality control, and flexible custom flatware services, supporting restaurants, hotels, distributors, and retail brands for long-term cooperation. For samples, quotations, or OEM/ODM services, please contact us.