Whether a set of flatware is clean, high-end and good in texture is often reflected in the “glossiness”. The polishing process is the key to determining the cutleries’ visual and tactile texture. As a leading stainless steel flatware manufacturer, Mcallen introduces the polish stainless steel flatware common methods, process flow and maintenance suggestions to help you better understand the process logic.

Why is it so important to polish stainless steel flatware?

Polishing is the guarantee of the beautiful appearance and practical performance of stainless steel flatware:

Improve texture: The high gloss surface can present a mirror-like effect and improve the overall appearance.

Easy to clean: The surface is smoother and less likely to hide dirt, which helps with daily hygiene maintenance.

Enhance corrosion resistance: Remove minor flaws and reduce the risk of stains and rust.

Reflect brand grade: Stainless steel tableware with high gloss is more in line with the brand tone of mid-to-high-end restaurants.

Mcallen’s customized stainless steel flatware considers polishing effects at the beginning of design. Different series use mirror, brushed, matte and other effects according to the use requirements.

What are the common methods for polishing stainless steel flatware?

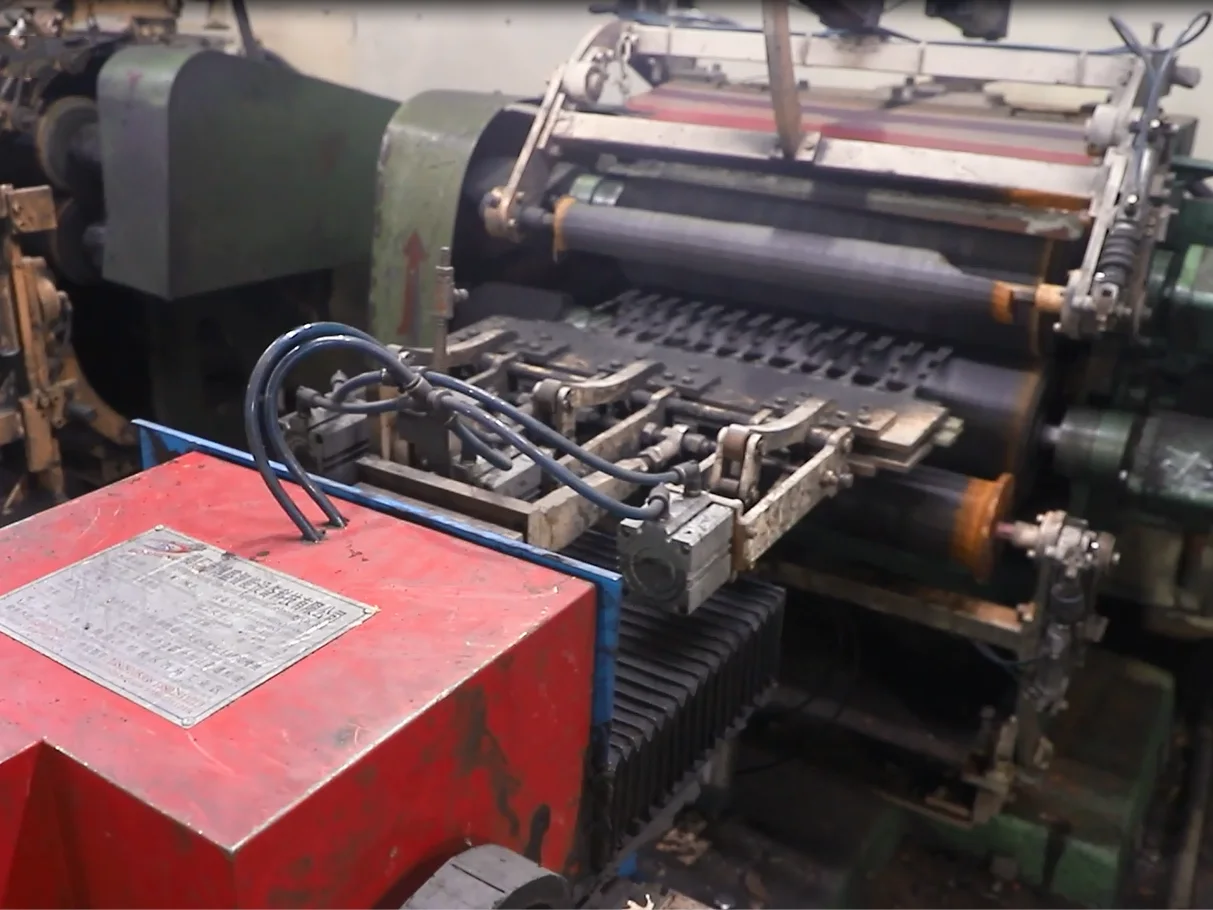

Mechanical polishing

This is the most common method for polishing stainless steel flatware. Use cloth wheels, wool wheels, etc. with polishing paste to repeatedly polish the surface of tableware to achieve mirror or mercerized effects, which is suitable for large-scale production of cutlery.

All Mcallen products use a multi-pass polishing process to ensure that each cutlery feels round and visually full.

Brushed polishing

It forms a delicate and uniform silk effect and creates a matte texture, which has been very popular in modern restaurants in recent years. Mcallen’s wholesale brushed stainless steel cutlery series is very popular.

Electrolytic polishing

It removes tiny particles through electrochemical action and is suitable for large-scale, high-precision cutlery products. It has a high cost, but can achieve extremely high cleanliness and corrosion resistance, and is often used in medical or high-end flatware fields.

Chemical polishing

Use chemical liquid to corrode microscopic burrs to make the surface smooth and shiny, which is often used for stainless steel flatware with complex shapes.

A brief description of the stainless steel flatware polishing process

Our stainless steel flatware polishing process pursues brightness and pays more attention to hand comfort and consistency:

Primary grinding: Use a coarse grinding wheel to grind and remove burrs and welds.

Intermediate grinding and polishing: Shape and polish edges and transition areas.

Fine polishing: Use cloth wheels and polishing wax to create mirror or matte effects.

Surface treatment: Choose titanium plating, electrophoresis and other methods to color according to customer needs.

Quality inspection and cleaning: Use ultrasonic cleaning to remove residual wax stains and dust.

Packaging and warehousing: After each set of products is inspected and qualified, they are packaged according to export standards.

How to judge the polishing quality when purchasing?

When purchasing, you can quickly judge the polishing level through the following points:

- See if the gloss is uniform and there are no obvious scratches.

- Touch whether it feels smooth and there are no piercing edges.

- Compare different styles to see if there is a batch color difference.

- Check if there is a mirror reflection when placed under light.

Mcallen can provide free samples for customers to observe the polishing details and feel the differences of the products up close.

Maintenance suggestions to extend the stainless steel gloss

Wash promptly after use to avoid seasoning and food residue.

Do not use rough objects such as steel wool to wipe the surface.

Regularly use a polishing cloth or stainless steel care agent to gently wipe the surface.

Avoid soaking in acidic and alkaline cleaning liquids for a long time.

Conclusion

Mcallen provides high-quality stainless steel flatware wholesale, customization, and export services. Whether you are pursuing mirror gloss, minimalist brushed, or retro matte, we can provide the corresponding polishing style and customize it according to your brand positioning. Contact us for a solution.