For the modern stainless steel flatware market, customization defines competitiveness. For purchasers in hospitality, retail, and catering industries, one of the most common challenges in sourcing custom stainless steel flatware is MOQ, or Minimum Order Quantity. Finding the ideal MOQ for custom flatware orders is not just about numbers; it’s about balancing flexibility, cost efficiency, and brand growth. Mcallen, a professional stainless steel cutlery set manufacturer in China, we understand that every client needs a tailored MOQ strategy.

Why MOQ Matters for B2B Flatware Purchasers

MOQ determines the smallest batch a factory will produce per design or SKU. For B2B buyers, MOQ directly affects budget control, product testing, and market flexibility. Initial investment, inventory planning, and the ability to test new designs or materials before mass rollout are all influenced by MOQ.

However, many factories set MOQs that are too high, typically 3,000 to 5,000 sets per design, making it difficult for small to mid-size importers or brand startups to launch efficiently. Mcallen adopts a flexible MOQ policy, offering low MOQ flatware manufacturing options that fit various business scales and distribution models.

Key Factors That Influence MOQ for Custom Flatware

Understanding what affects MOQ helps buyers make smarter purchasing decisions.

Material Grade and Raw Material Cost

Different grades of stainless steel — such as 18/10, 18/8, and 18/0- impact the production process, cost, and required volume. Mcallen’s long-term partnerships with raw material suppliers ensure stable stainless steel sourcing and optimized MOQ for custom flatware orders.

Product Complexity and Design Process

Flatware with unique handle designs, special molds, or PVD color finishes usually requires a higher MOQ to justify tooling and setup costs. We offer in-house mold development and surface treatment, including mirror, brushed, sandblasted, or titanium gold finishes to reduce switching costs and allow small batch OEM and ODM flatware production.

Branding and Packaging Customization

Custom logo engraving, silk printing, or premium gift packaging increases packaging variety and sometimes MOQ. Mcallen provides multiple packaging solutions, including neutral boxes, kraft cartons, and luxury gift sets, making it easier for distributors and retailers to manage brand consistency with flexible volume.

Why do Many Factories Require a High MOQ? How Mcallen Solves It?

Most stainless steel flatware factories set high MOQ thresholds due to production efficiency concerns, including raw material batch procurement, mold setup, machine adjustment, and packaging standardization. For small or first-time buyers, these conditions create cash flow pressure and inventory risks.

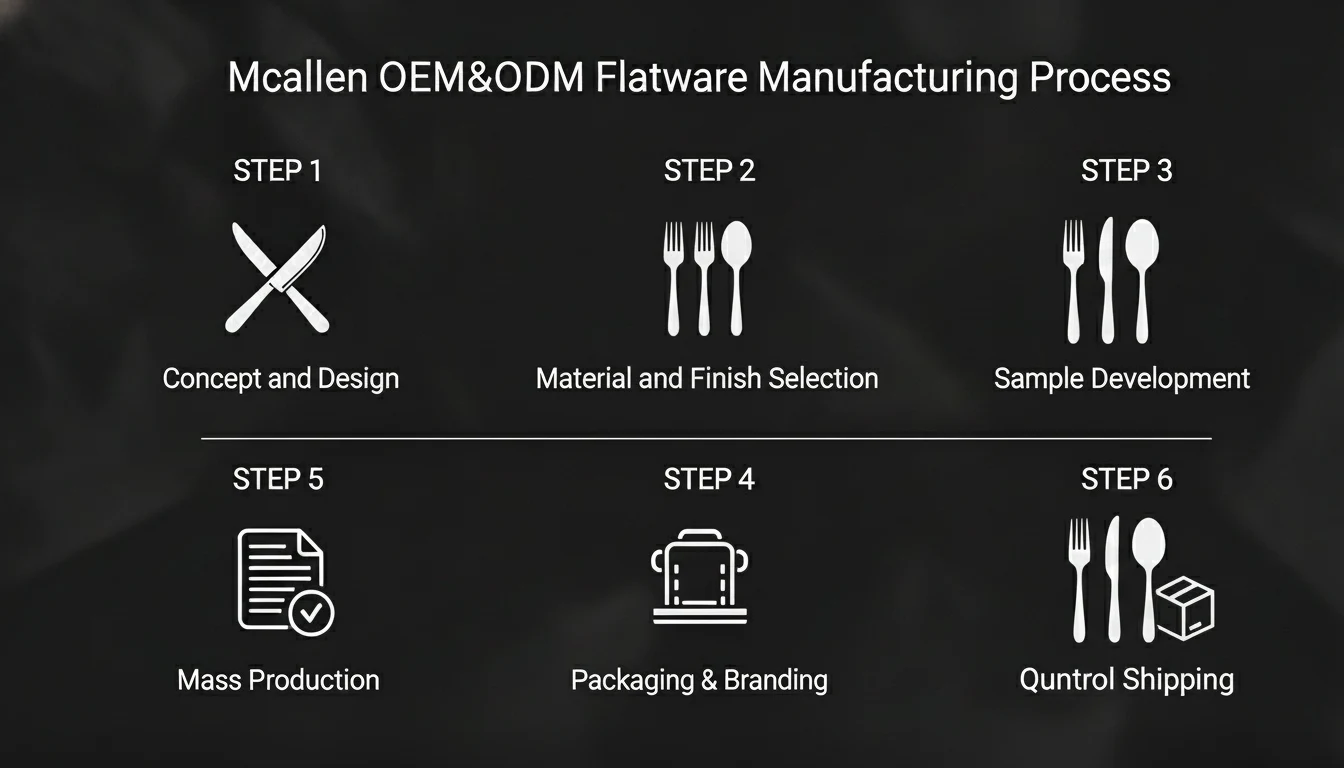

Mcallen solves these problems through flexible MOQ options, starting from 1,000 sets for test or niche orders, semi-automated production lines for faster switching between designs, in-house tooling and mold room to lower setup costs, and integrated OEM and ODM stainless steel cutlery set services supporting clients from concept to finished product. Whether testing a new market or scaling an established brand, McAllen ensures your flatware order quantity fits your real business needs.

Mcallen’s Flexible MOQ Model: From Trial Orders to Full-Scale OEM

To support global customers, Mcallen offers a three-stage MOQ cooperation model designed to match business development phases.

Step 1: Trial Orders starting from 1,000 Sets

Perfect for new designs or market testing. We provide ready-to-customize ODM flatware designs with your logo and color options.

Step 2: Stable Wholesale Cooperation

For distributors and hospitality chains needing regular replenishment, production cycles and inventory levels are planned to ensurea steady supply and lower unit cost.

Step 3: Exclusive OEM Partnership

For established brands seeking private mold development and long-term customization, Mcallen provides full OEM flatware solutions from design to private label packaging, helping your brand own exclusive tableware collections.

How to Choose the Right MOQ Strategy for Your Business

Selecting an MOQ that fits your operation can optimize costs and reduce risk. Start by defining your market type, whether hotel, catering, retail, or promotional use. Select materials and finishes early as they impact cost and MOQ. Start small and scale smart by using ODM models to test, then shift to OEM exclusives. Request samples first to verify weight, balance, and polish quality before mass production. Confirm packaging and branding files early to avoid production delays.

Mcallen’s professional export team provides one-on-one consultation, ensuring smooth progress from design to shipment.

Conclusion

There’s no universal MOQ for custom flatware orders; the best MOQ is the one that balances your brand’s current capacity, market strategy, and cash flow. Our customization is made more accessible through flexible MOQ options, in-house design support, and efficient production capacity. Whether launching a new collection or expanding your private label, Mcallen is your reliable partner for OEM and ODM stainless steel flatware manufacturing. Contact us today to start your next custom flatware project with a trusted manufacturer in China.